Our Products

- Home

- Our Products

Automatic Motor Type Test System

Automatic Motor Type Test Systems offered by us is designed to successfully fulfill typical needs of electric motor manufacturers. We manufacture test system for Induction motors, PMSM motors, BLDC motors etc. We have successfully designed test system ranging from 0.12Kw to 400Kw. These Automatic Motor Test Systems consists of Test bed, Loading mechanism, Measuring instruments, Control Panel and Software. For simulating field conditions, different types of loading mechanisms can be used. We also offer regenerative, non-regenerative drive and dynamometers loading. Proper care is also taken to install test motors with minimum installation time as well as operator’s safety. Motor type test software conducts following test automatically.

Motor type test software conducts following test automatically.

- No load test

- Locked rotor test

- Speed Torque Test

- Heat Run Test

- Part Load Test

- No Load (hot) Test

Features:

- After completion of tests required reports are generated.

- Software works in client server environment that ensures availability of reports on network

- Reports are generated as per national or international standard requirements.

Automatic Motor Routine Test System

Automatic motor routine test systems offered by us are complete test solution for electric motor manufacturers. We have designed test system from 0.1A to 800A range of motors. These motor test systems consist of Measuring instruments, Control panel, PLC and Software. Further, these Control panel route incoming power supply to motor leads. Measuring instruments mainly consists of transducers which record field data and transfer to computer. The customized motor routine test software provides complete environment for motor testing. Software also stores master data of every model and system automatically performs following tests.

Tests :

- Insulation Resistance Test

- Coil Resistance Test

- Low Voltage Test

- High voltage test

- Reversal test

- Locked rotor test

- No load Test

Features :

- After completion of tests required reports are generated.

- Software works in client server environment that ensures availability of reports on network.

- These test systems can be designed to match motor manufacturing production time.

Automatic Pump Test System

The Automatic Pump Testing System is a complete solution for pump testing process in pump industry. The aim of Automatic Pump Testing System is to remove the human errors associated with testing of equipment, measurement, and recording of data. Use of computer provide a quick and reliable method of performing repeated tests that yield consistent data. The system not only improves quality but dramatically increases efficiency of pump testing section. We have manufactured automatic pump test system for surface and submersible pumps of electric and solar types. The system can perform following tests.

- Pump performance test

- Temperature rise test

- NPSH test

Features :

- Multiple test lines can be controlled with software.

- Pump Test Software automatically captures required readings, regulate dimmers as well as control valves.

- The system automates pump testing process, making report & curve generation very simple & easy as well as frees one from tedious calculations and repetitive tasks.

- It provides ways for comparing test data/curve with master data/curve

- The system can be customized to suit specific needs of particular pump manufacturing Industry

Pump Selection Software

For selecting a pump the program searches the database and creates a list of all pump models capable of performing given duty. The user can then select a particular model from list and can view / print the specifications of the model along with its characteristic curves. The program will automatically select a suitable motor for the pump and show its specifications also.

There is also provision for calculating head losses as per various pipe sizes and calculating energy requirement. The other salient features of the software are as follows

- The software is highly user friendly, so that any person with little or no technical knowledge can use it for pump selection.

- Selection portal can be access from any computer with internet facility.

- Password protection for admin and users, with unlimited users creation.

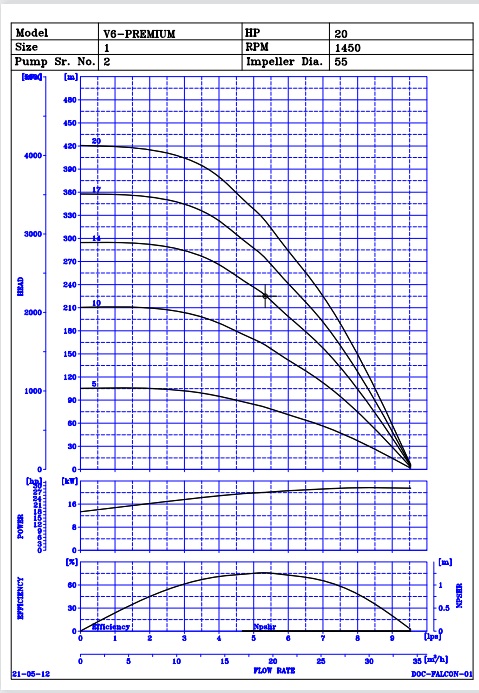

Family Curve Software

This program is a very useful for generating performance curves of different pump models by giving the required data. It generates curves of head, power, efficiency and npshr v/s discharge. Different units can be selected for different parameters eg. discharge can be given in lpm and shown in gpm and cu.m/hr, head can be shown in meter and feet, power can be shown in kilowatt and hp, etc. All the parameters are to be fed in desired units to the program, the program then decides the limits for all parameters and suggests suitable grid spacing values, which can be modified by the user. The program adjusts the scale to fit the graphs in A4 size paper sheet. The program then draws the required curves. For submersible pumps head curves of different stages can be generated for a model by specifying head values for single stage pump and number of stages for various head curves. The program also draws a table of values used for generating curves.

Different units can be selected for different parameters like:

- Discharge can be given in lpm and shown in gpm and cu. m/hr

- Head can be shown in meter & feet

- Power can be shown in kilowatt and HP

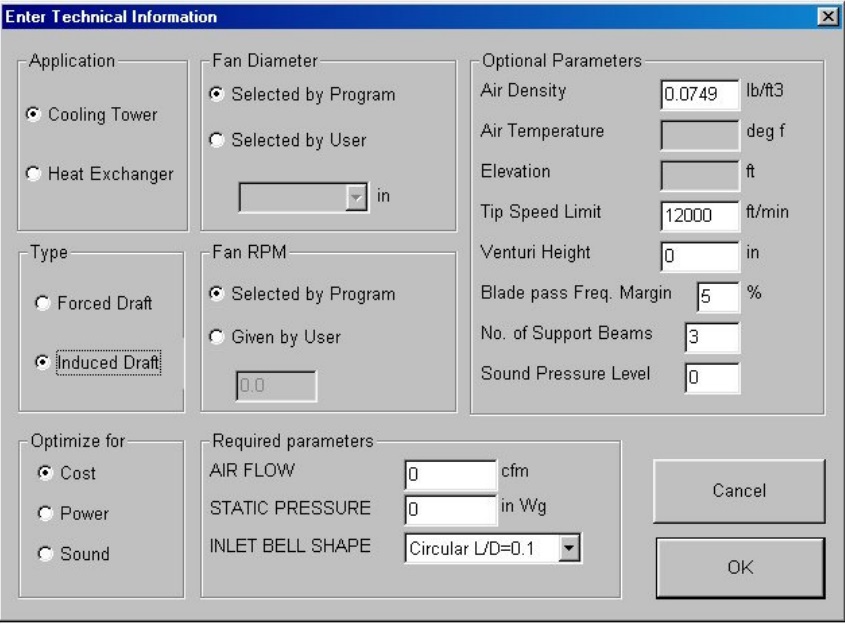

Fan Selection Software

For selecting a fan the user is asked to provide information like air flow rate, static pressure and inlet bell shape. Optionally the user can also provide air density / temperature and altitude, allowable tip speed, number of support beams, venturi height, etc., otherwise the program uses default values of these parameters. The user also needs to specify fan diameter and fan speed, if they are available with the user, else the program will decide the fan diameter and fan speed. A screen like the one shown below is displayed to accept data from user. Before this the user is also asked to select system of units, Metric or I-P. Depending upon the data supplied by the user, the fan database is searched for fans performing required duty. The best-suited fan model depending on the criteria for optimization is shown to the user. The performance curves, specification sheet and speed-torque curve of the selected fan can be viewed and printed. Appropriate error messages are shown when the required duty is not met. The program displays a specification sheet like the one shown below after fan selection. The following screen is for Metric units. The parameters in specification sheet can be customized to match fan manufacturing company’s requirements. Following screen shows one of the forms used to feed fan data in fan database.

Transformer Testing Software

Transformer Testing software is a solution for testing of new as well as repaired transformers. It uses an interface to WT series power analyzer for online display of electrical parameters and capturing required readings. Winding resistance of HV side and LV side are measured and fed in software along with Insulation resistance values.

No Load test is conducted on transformer, In Open circuit test / No Load Test the voltage at rated frequency is applied to that LV side with the help of a variac of variable ratio auto transformer and data is captured automatically via power analyzer. The HV side of the transformer is kept open.

In Short Circuit Test / Load Loss Test A low voltage of around 5-10% is appliedvto that HV side with the help of a variac (i.e. a variable ratio auto transformer )vand the LV side of the transformer is short circuited. Electrical parameters arevonline displayed on screen, with the help of variac applied voltage is slowly increased until the current reading reaches equal to the rated current of the HV side. Data is captured directly via power analyzer.

The software calculates the load loss and impedance voltage (%) and declares the transformer as PASS / FAIL as per predefined criteria.The test data is stored and can be retrieved easily in future when needed. Reports can be stored at web server for worldwide access.

Software for Bar Coding

Barcode software is a technology which reduces human involvement in data entry and collection, thereby also reducing error and time. We offer bar code software for packaging industries, which can be customized for other applications also. The software print the barcodes stickers on production line. These stickers have information about company name, contact details, product technical details and price details. Stickers printed for various items are pasted on cartons/products during manufacturing stage that helps in easing out packaging details. Hand held bar code scanners reads the coded data from each production line. Thus operator do not have to gain familiarity with an entire inventory or pricing procedure. The data is transferred to the central server. Our user-friendly barcode software successfully maintaining production records and packaging details. Since software work in client server environment, so reports are available on intranet. We constantly improve our software with the upcoming technology. We have upgraded our software to incorporate two dimensional bar code system. Which offer high capacity information in less area.

Features :

- Details of component used in assembly can also be maintained with the help of barcode stickers

- Barcodes helps in reducing data entry and improves accuracy of data

- Tracking of items produced also becomes easy with help of bar code systems

- Various types of reports can also be generated and customized as per the requirements